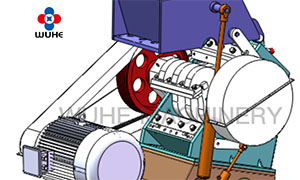

GSP seri pipa crusher

Parameter utama

| Model | daya(KW) | Rpm(R/MIN) | Maks PipeD(MM) |

| GSP-500 | 22-37 | 430 | Ф250 |

| GSP-700 | 37-55 | 410 | Ф400 |

| Hopper pakan | ● dirancang khusus dipakani hopper supaya materi splashing. ● marem requirement khusus kanggo mesthekake lampahing dipakani |

rak | ● Desain wangun khusus, kekuatan dhuwur, pangopènan gampang ● Optimasi struktur mbenakake piso tetep ● Ing quenching lan tempering, kaku relief perawatan panas ● proses CNC ● cara mbukak rak: hydraulic ● Bahan awak: 16Mn |

| Rotator

| ● Lading ana ing susunan ramping ● Jarak blades 0.5mm ● welding baja kualitas dhuwur ● Ing quenching lan tempering, kaku relief perawatan panas ● proses CNC ● Kalibrasi imbangan dinamis ● Bahan blades: SKD-11 |

| bantalan rotor | ● Pedestal bantalan sing dipasang, kanggo nyegah bledug menyang bantalan ● proses CNC ● Dhuwur tliti, operasi stabil |

| bolong | ● Kasedhiya saka bolong lan bolong tray ● Ukuran bolong kudu dirancang miturut materi sing beda ● proses CNC ● Bahan bolong: 16Mn ● Cara bukaan bolong: hidrolik |

| nyopir | ● SBP sabuk drive efisien dhuwur ● torsi dhuwur, gearbox lumahing hard |

| Sistem hidrolik | ● Tekanan, pangaturan aliran ● Tekanan sistem: >15Mpa |

| Piranti nyedhot | ● Silo baja tahan karat ● tas daur ulang bubuk |

Tulis pesen sampeyan ing kene lan kirimake menyang kita